For complex machining, VISI allows us to handle high speed and 5-axis operations, as well as traditional milling.”

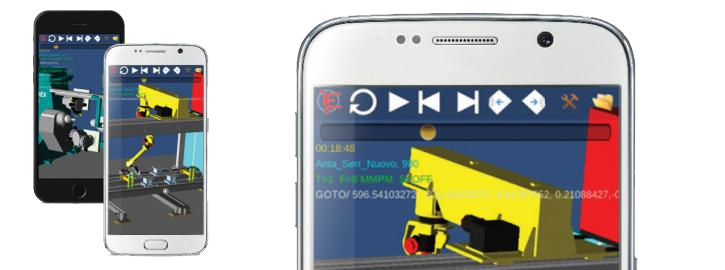

“All holes are recognized automatically and the correct machining cycle applied. He says that as VISI is an integrated system, machining individual plates can be accomplished automatically through feature recognition. Machines often work round-the-clock, so a simulator is indispensable for operations in unattended areas" says Alessandro Corà.Īmong the most popular VISI functionality, according to Marco Dal Bianco, is the ability to automatically recognize manufacturing features such as holes and pockets, and to generate the appropriate toolpaths. "For complex 5-axis machining, it's crucial to be able to drive almost with ‘your eyes closed,’ avoiding collisions and tool issues that could compromise the entire machining of the workpiece. To satisfy this need, an application for interfacing VISI with Eureka has been developed, transferring all part and CNC machine models, tool parameters and toolpath data from VISI to the simulator. The ability to move from solid to superficial model and vice versa also gives maximum freedom in managing CAD modifications.Īnother key requirement for Modulo Tre was having a reliable kinematic G-code simulator, to virtually walk through the machining process before sending to the machine, especially during unattended shifts. The solid closure of a surface model eliminates any design problems that may arise, making it easier to remove or add holes, fittings and other modelling features. To check tolerances, the old and new surface can be compared, and the maximum and minimum distances checked, as well as the curvature difference. Where surfaces are corrupt or missing, VISI automatically produces edge curves that make it easy to create new surface data. With VISI Modelling, small errors found in imported model surfaces can be automatically healed during stitching, avoiding the time-consuming process of constructing very small surfaces to close tolerance gaps.

#EUREKA CNC SIMULATOR DOWNLOAD SOFTWARE#

But with 5-axis machining this becomes very complex, so we decided to replace the previous software and introduce VISI, which is fast and intuitive, even on corrections and modifications that often have to be applied to the customer’s original CAD model for manufacturing purposes." “In the past, we had to leave the CAM environment to make any modifications or corrections and then reset it all. Our primary requirement was having an integrated CAD and CAM system,” explains Alessandro Corà. The 5-axis logic created the need for reliable and simple CAD/CAM integration, which led Modulo Tre – based at Schio, Northern Vicenza, in Italy – to introduce the VISI portfolio of 3D CAD Modelling, and 2D > 5-Axis Machining, interfaced with the Eureka kinematics simulator. And they have now started to operate in the aeronautics field, creating flanges which are then assembled by a nearby company. They also manufacture turbochargers for the hydroelectric industry and work in the molding sector on both sheet metal deformation and thermoforming – in particular producing interior panels for the automotive sector. The complexity of orders has also increased, and today the company can carry out any customer-designed milling work. Alessandro Corà describes it as a "pioneering" choice which opened up new horizons, giving them inroads into the energy industry, producing hydroelectric, oil, gas and wind components, along with parts for automotive companies and, more recently, the aerospace sector.

The decision to move to continuous 5-axis route around seven years ago, when they invested in a SORALUCE FP 12000, a floor type multi-purpose milling and boring center. They typically work with stainless steel, light and super alloys. Adopting 5-axis technology means they can machine a wide range of components such as hollow and grooved profiles, with deep and sloping holes, without material constraints. Modulo Tre, which was founded in 1995 by partners Alessandro Corà, Marco Dal Bianco and Gilberto Dal Pozzo, now has a large fleet of latest generation machines capable of producing workpieces up to 12000 mm (x), 1500 mm (y) and 3200 mm (z). One of the early adopters to introduce simultaneous 5-axis machining into its region, chose the VISI integrated CAD/ CAM system from Vero Software, to drive its CNC machine tools.

0 kommentar(er)

0 kommentar(er)